What is ProdOptix ?

ProdOptix is a Saudi-developed Manufacturing Execution System (MES) platform designed to digitally

manage, monitor, and optimize manufacturing operations in real time across the shop floor and

enterprise levels. It provides end-to-end visibility, control, and execution of production

activities based on the ISA-95 standard hierarchy, ensuring structured integration between

enterprise systems and industrial operations.

ProdOptix is 100% Saudi-made — architected, engineered, and owned locally — and is

not a white-label or rebranded product. The platform’s core architecture, workflows, dashboards, and

functional modules are built in the Kingdom to address the real operational challenges faced by Saudi

manufacturers, including local production practices, industrial environments, and digital

transformation goals.

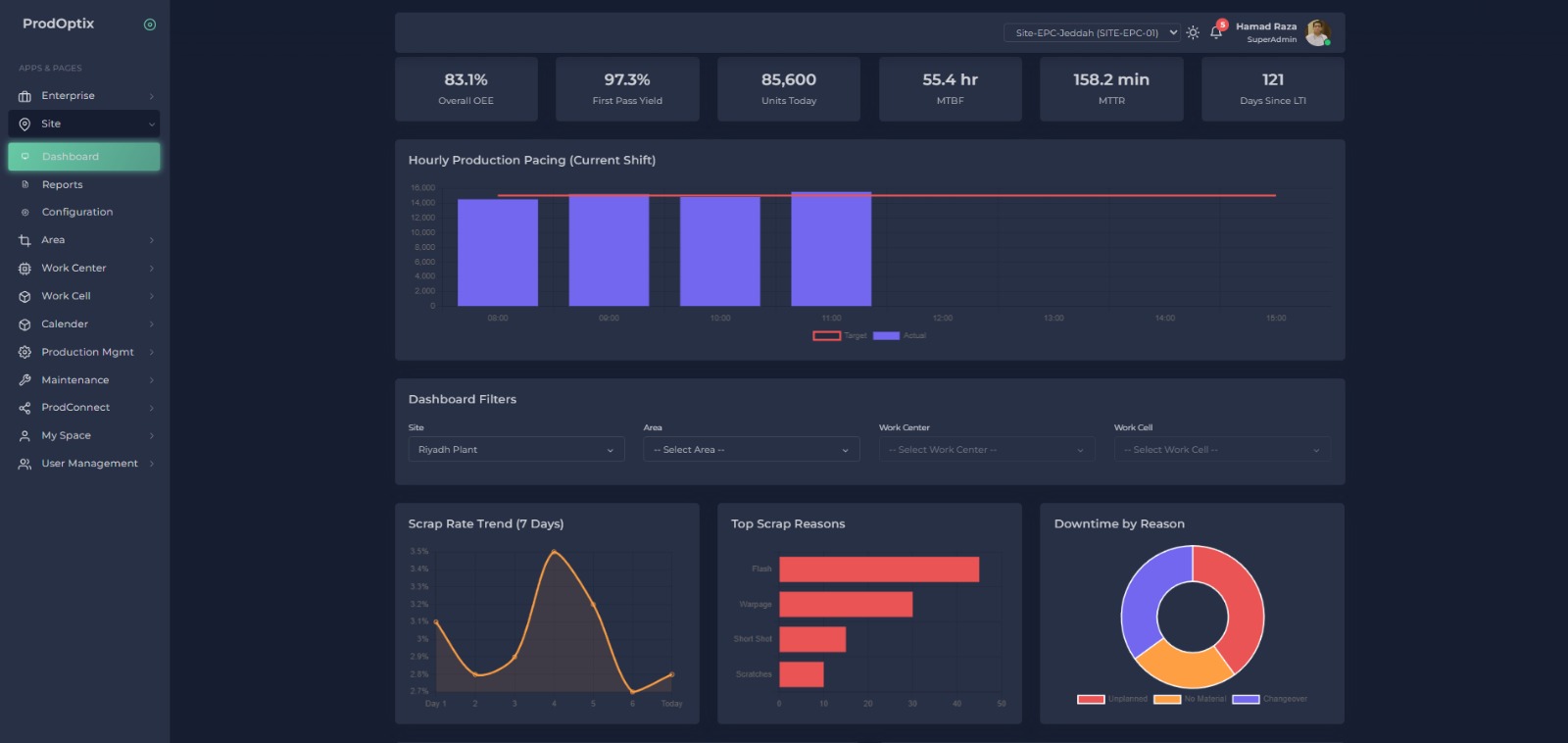

The platform delivers real-time shop-floor monitoring, work center execution control, and live KPIs

such as OEE, quality, downtime, and productivity, enabling manufacturers to move away from manual

data collection toward data-driven decision-making. ProdOptix integrates seamlessly with ERP systems

(e.g., Microsoft Dynamics), OPC UA, and IoT devices, creating a unified data flow from machines to

management dashboards.

All designed to support paperless operations, reduce downtime, improve throughput, and enhance

overall manufacturing performance. By combining local development, modern MES architecture, and

real-time industrial data, ProdOptix enables manufacturers to modernize operations, improve OEE, and

achieve scalable, future-ready smart manufacturing — while supporting local content and national

industrial digitalization initiatives.

Who Needs MES and Why?

A Manufacturing Execution System (MES) is crucial for industries that require

real-time monitoring, process optimization, and seamless production workflows. It helps businesses

improve efficiency, reduce costs, and ensure product quality.

01.

Large-Scale Manufacturing Companies

To manage high-volume production, track materials, and ensure product

consistency.

02.

Automotive & Aerospace Industries

To streamline complex assembly processes and maintain compliance with

strict industry regulations.

03.

Small & Medium Enterprises (SMEs)

To optimize resources, reduce waste, and compete with larger

manufacturers by increasing efficiency.

04.

Electronics & High-Tech Manufacturing

To track component usage, improve product traceability, and reduce

errors.

Most Asked Questions

MES connects machines, operators, and enterprise systems to collect,

analyze, and optimize production data. It ensures seamless communication between the shop

floor and business operations.

Key benefits include:

Real-time production monitoring

Improved product quality

Enhanced efficiency and reduced downtime,

Better compliance with industry standards

Optimized inventory and resource management

MES is widely used in industries such as automotive, aerospace,

electronics, pharmaceuticals, food & beverage, and heavy manufacturing to improve production

efficiency and ensure compliance.

No. ProdOptix is not a white-label system. It is a 100% Saudi-made MES

platform, fully designed, developed, and owned locally. The system’s core architecture,

source logic, functional modules, and roadmap are built in-house in Saudi Arabia and are not

rebranded, resold, or derived from any third-party MES product.

Yes. ProdOptix is fully developed, engineered, and maintained in Saudi

Arabia, with local ownership of the platform architecture, modules, and roadmap..

Yes, MES can leverage IoT sensors for real-time data collection and AI

for predictive maintenance, anomaly detection, and process optimization.

Costs vary based on company size, customization needs, integration

complexity, and licensing fees. ROI is typically realized through efficiency gains and cost

savings.